In the pharmaceutical industry, the quality of treated water is of paramount importance. Water serves as a critical component in various manufacturing processes, making it crucial to ensure its purity and adherence to stringent standards.

As water treatment plants in the pharma industry seek optimal filtration solutions, glass filter media has emerged as a superior choice. In this blog, we explore why glass filter media should be used in water treatment plants for the pharma industry, focusing on the high quality of treated water, certification requirements, advantages over traditional sand media, and the industry’s demand for excellence.

Ensuring the Highest Quality of Treated Water

Pharmaceutical manufacturing necessitates water of the highest quality due to its direct impact on product efficacy, safety, and compliance. The stringent standards set by regulatory bodies, such as the U.S. Food and Drug Administration (FDA), demand pharmaceutical companies to maintain impeccable water quality throughout their processes. Glass filter media offers a solution that meets these demanding requirements. Its unique properties enable efficient removal of suspended solids, bacteria, and impurities, ensuring the production of ultra-pure water that complies with the most stringent industry standards.

The use for high quality process water highly impacts the quality of the end product being manufactured in these facilities, be it solvents, APIs, syringes, vials, etc. These products are also exported to foreign markets where the industry standards and customer requirements are extremely stringent as well. Customers also carry out audits at these pharma facilities. In such cases, having high quality of process water really helps out as well.

Accreditation and Certification

To guarantee the reliability and credibility of filtration media, accreditation and certification play a crucial role. Glass filter media designed for water treatment plants in the pharma industry should obtain certifications from respected organizations such as NSF International, Bureau Veritas, Absence Biofilm, etc. These certifications ensure that the glass media meets rigorous standards for quality, performance, and safety in each and every batch manufactured and no anomalies.

- NSF-certified glass filter media offers reassurance to pharmaceutical manufacturers, assuring them of consistent water quality, durability, and compliance with industry best practices.

- Absence of Biofilm certification ensures that the media will prevent biofilm formation as well as the formation of channels in the bed, which usually reduces efficiency.

- Finally, Bureau Veritas certification ensures that there is absence of free silica in our glass media and provides Fresh water treatment authorization.

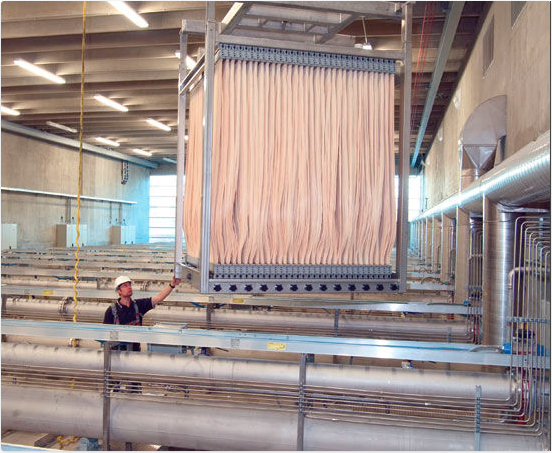

Advantages of Glass Filter Media

Compared to traditional media like sand, glass filter media offers several key advantages for water treatment plants in the pharma industry.

- Firstly, glass media provides superior filtration efficiency due to its highly uniform particle size, enabling the removal of smaller particles and microorganisms. This enhanced efficiency translates into cleaner water, minimizing the risk of contaminants in pharmaceutical processes.

- Secondly, glass filter media exhibits exceptional chemical resistance and stability, ensuring that it does not introduce any undesirable substances into the water during the filtration process. This quality is particularly crucial for pharmaceutical applications where even trace amounts of impurities can impact product quality and safety.

- Thirdly, glass media has a longer lifespan and requires less frequent backwashing compared to sand and other conventional media. This leads to reduced maintenance and operational costs, making it a cost-effective long-term solution.

Water treatment plants in the pharma industry face unique challenges in providing high-quality treated water that meets strict industry standards.

Glass filter media emerges as the optimal choice due to its superior filtration efficiency, longevity, improved water quality, and reduced maintenance requirements. Additionally, the certifications and accreditations obtained by glass media further reinforce its reliability and adherence to industry standards.

Get in touch with us at info@purewaterent.net to know more about our offerings in this space and how we can help you and your customers obtain the highest level of water purification.

About The Author: Pure Water

More posts by Pure Water